© 2026 Ferroplus.lv

- info@ferroplus.lv

- +371 26077715

- “Mehaniskas darbnicas”, Jaunolaine, LV-2114, Latvia

MIG and MAG welding

(Metal Inert Gas and Metal Active Gas)

We offer MIG and MAG welding services for different steel grades. Biggest difference between those two processes is used gas. Sometime in the process is used gases mixes, that is important to know to get perfect seams. Experienced welders know about those nuances and chouse correct gases by default. Our biggest machines can weld with the power up to 350Amps, that allow to weld tick materials and heat the workpieces to necessary temperature. Process is easy to adjust with the modern machines, that help to get perfect results. Usually with MIG and MAG method is treated materials starting from 3mm thickness, maximum thickness doesn’t exist.

TIG welding

(tungsten inert gas )

We offer TIG welding services for stainless steel and other non-ferrous materials mostly. Process going relatively slow, that why process control is much bigger for each mm of seam, compering with MIG/MAG method. Our machines with cooling torch can speed up the process and save production time. For pipes welding back gasses is used on regular base, that prevent material oxidation from opposite welding side. Welds it self looks like artwork, that why process is used for decorative welds and its another good side of the process. Usually, TIG method is used for thin materials up to 3mm, pipes or other important parts. TIG weldingtype is very popular in the food industry.

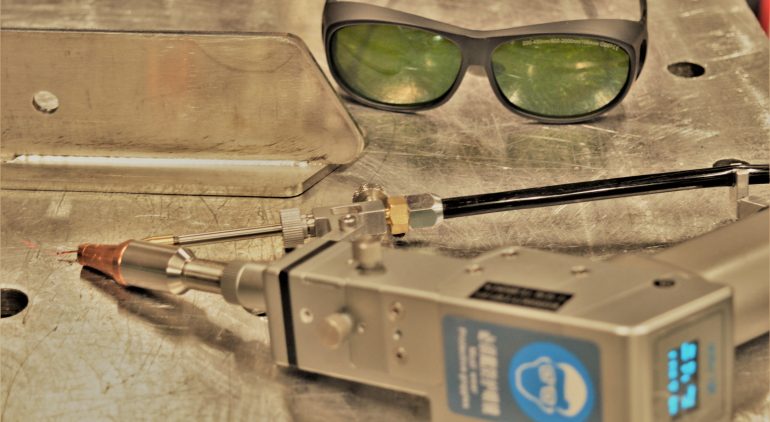

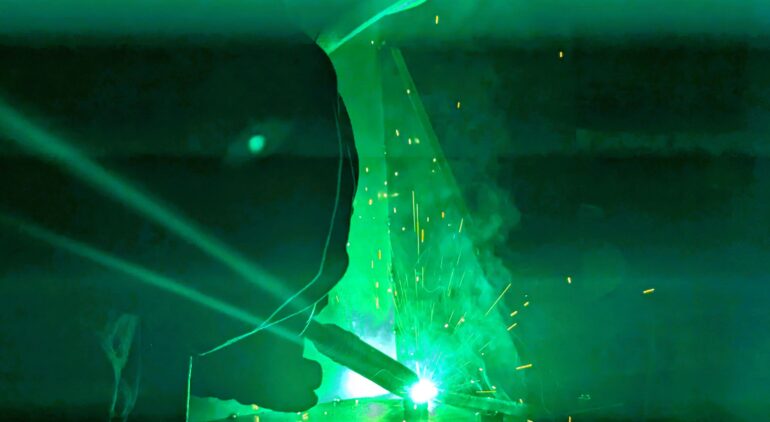

Laser welding

We offer Laser welding services for any steel grade and type. Newest method, in nearest years will become popular. Fast process time, up to 10 times faster compared to TIG welding process can significantly reduce costs. Local reduced heat impacts on the work pieces prevent distortions and save visual view after the process. With this method can be welded materials from 0.1mm up to 5mm. Our performed tests show good strength ability.